1

/

of

1

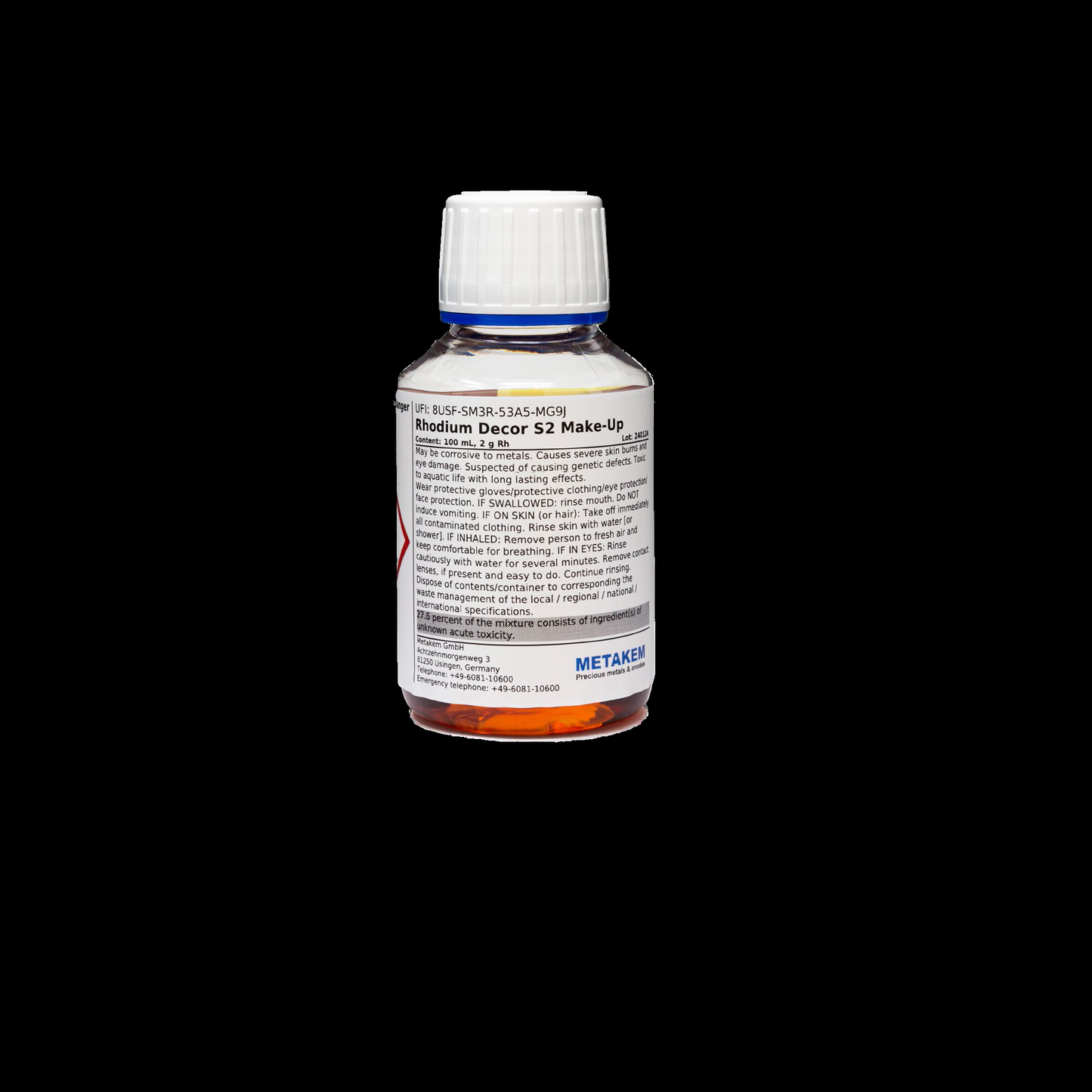

Manufactured by Metakem, sold by Nano Cats GmbH

Rhodium Decor S2

Rhodium Decor S2

Regular price

€1.040,00 EUR

Regular price

Sale price

€1.040,00 EUR

Unit price

/

per

Couldn't load pickup availability

Rhodium-Decor-S2

High-quality rhodium electrolyte for brilliant white coatings. Suitable for decorative and functional applications, it deposits extremely bright, brilliant white layers. Applicable for rack and barrel plating. This easy-to-use electrolyte is characterized by outstanding throwing power and high plating speed. Crack-free coating thicknesses up to 3.0 μm are achievable.

| Property / Parameter | Value / Description |

|---|---|

| Metal | Rhodium |

| Atomic Number | 45 |

| Atomic Weight | 102.91 |

| Concentrate Content | 2 g Rh per 100 ml |

| Bath Color | red-brown solution |

| Rhodium Content in Electrolyte | 2 g Rh/l |

| pH Value | <1 |

| Operating Temperature | 35 °C (range: 25 – 50 °C) |

| Cathodic Current Density | 1 A/dm² (range: 0.5 – 2.5 A/dm²) |

| Voltage | 2 V (range: 1.8 – 2.2 V) |

| Deposition Rate | 0.08 μm/min at 1 A/dm² |

| Deposition Efficiency | 9.4 mg Rh/Amin at 1 A/dm² and 35 °C |

| Current Efficiency | 32% at 1 A/dm² and 35 °C |

| Anode Material | Platinized titanium or MMO titanium anodes |

| Anode to Cathode Ratio | Minimum 1:1 |

Coating Properties

- Pure rhodium coatings

- Brilliant white color, >90 referenced to DIN 5033

- Hardness: 800 – 900 HV

- Layer density: approx. 12.4 g/cm³

- Maximum layer thickness: 1.5 μm for decorative, up to 3.0 μm for non-decorative uses

Bath Preparation and Maintenance

- Slowly stir 100 ml of Rhodium Decor S2 stock concentrate with 2 g of Rh into 800 ml of deionized water and then fill up to 1 liter with deionized water.

- Operation conditions: Start with 2 g Rh/l and working up to i) 1.6 g Rh/l when adding, and ii) 0.25 g Rh/l during final work-out

- Sulfuric acid concentration 25 g/l after preparation with 2 g Rh/l.

- pH below 1, no routine monitoring needed.

- Suitable stirring to remove hydrogen bubbles necessary.

Usage Recommendations

- Pre-clean surfaces and use nickel underlayer for lead, zinc, tin, aluminum, iron before rhodium plating.

- Carbon treatment for organic contamination recommended if needed without removing additives

- Analytical control of Rh and sulfuric acid content advised.

- Bath can be operated down to 0.4 g Rh/l with declining but acceptable current efficiency and stable coating quality.

Share